-

-

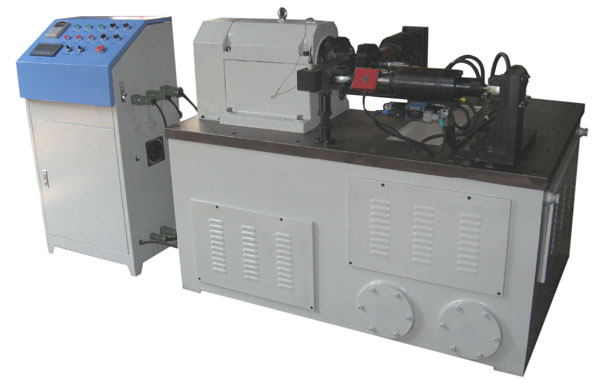

Product name: Testing machines for bearings for automobile

-

-

Price: ASK

-

-

Post date: 2013-06-08

-

-

Stock Quantity:

-

Description:

These testing machines realize the computer auto control, with the auto control of test parameters, auto printing of record and auto alarm and stop. The electric-hydraulic proportioning and electric-hydraulic servo control technology realizes the closed loop control of load. The frequency variable speed regulation technology realizes the stepless speed regulation of test equipment. The industrial computer control technology realizes the auto control and intelligent management of testing machine. The self-developed execution software under windows operation system can realize the multi-task management, with large power. 1. TAH3050Tf simulation testing machine for bearings of automobile wheel hub This testing machine is used in the simulation test for bearings of car wheel hubs. The tested bearing is mainly mounted in the structure of cantilever, able to realize the rotation of bearing inner ring or outer ring, able to simulate the speed spectrum, load spectrum, temperature spectrum and mounting conditions to have the test. Main technical parameters Bore dia. of tested bearing d=3050mm Max. radial load 15kN Max. axial load 10kN Max. speed 2000r/min Bearing ambient temperature 130 The radius of simulated tire 260350mm Control mode microcomputer auto control Test parameters speed, load, temperature, vibration, voltage, current 2. Release bearing simulated tester of TAC3050nT automobile clutch This tester can simulate the actual working condition of the combination of release bearing of automobile clutch and the spring squash. It can test the using life of release bearings. The release bearing can be released under the simulated working condition by mechanical method, according to the required parting and reunions frequency and process. It is stable. Main technical parameters Bore dia. of tested bearing 3050mm Max. axial load 1000N Max. speed 10000r/min Clutch frequency 2Hz Ambient temperature 150 Control mode microcomputer a

These testing machines realize the computer auto control, with the auto control of test parameters, auto printing of record and auto alarm and stop. The electric-hydraulic proportioning and electric-hydraulic servo control technology realizes the closed loop control of load. The frequency variable speed regulation technology realizes the stepless speed regulation of test equipment. The industrial computer control technology realizes the auto control and intelligent management of testing machine. The self-developed execution software under windows operation system can realize the multi-task management, with large power. 1. TAH3050Tf simulation testing machine for bearings of automobile wheel hub This testing machine is used in the simulation test for bearings of car wheel hubs. The tested bearing is mainly mounted in the structure of cantilever, able to realize the rotation of bearing inner ring or outer ring, able to simulate the speed spectrum, load spectrum, temperature spectrum and mounting conditions to have the test. Main technical parameters Bore dia. of tested bearing d=3050mm Max. radial load 15kN Max. axial load 10kN Max. speed 2000r/min Bearing ambient temperature 130 The radius of simulated tire 260350mm Control mode microcomputer auto control Test parameters speed, load, temperature, vibration, voltage, current 2. Release bearing simulated tester of TAC3050nT automobile clutch This tester can simulate the actual working condition of the combination of release bearing of automobile clutch and the spring squash. It can test the using life of release bearings. The release bearing can be released under the simulated working condition by mechanical method, according to the required parting and reunions frequency and process. It is stable. Main technical parameters Bore dia. of tested bearing 3050mm Max. axial load 1000N Max. speed 10000r/min Clutch frequency 2Hz Ambient temperature 150 Control mode microcomputer a